Working with PROFIL®

Learn about how we cover you from technical advisory through after-sales support with the PROFIL® closed loop solution.

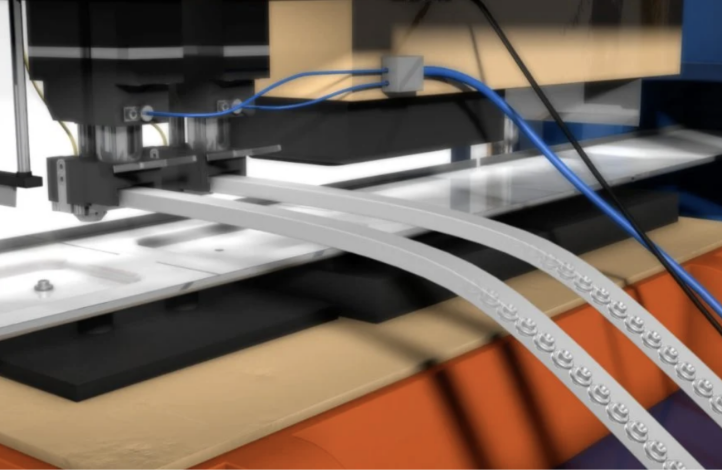

PROFIL® offers customers the ability to install our Mechanically Attached Fasteners (MAF) directly in their press lines for a fully automated solution. Benefits include:

Progressive die operations are very typical in the automotive space, as they enable quick production of parts with strict tolerances. PROFIL® works with our customers to integrate seamlessly within this fast-paced stamping environment, ensuring that our mechanically attached fasteners are installed in-line, saving time and eliminating secondary operations.

Transfer die operations are used in manufacturing where multiple presses are used in tandem for stamping. This process is typically used for large panels with complex geometry. PROFIL® works with our customers to integrate seamlessly into their transfer die operations, installing our Mechanically Attached Fasteners (MAF) directly into each application as it’s assembled.

PROFIL® tooling is used in C-Frame installation processes. PROFIL® C-frame presses enable customers to install fasteners manually or via robotic operations.

Manual – Operator-based installation for low volume,

single parts and prototypes

Robotic – Stationary C-frame: Robot moves the sheet metal component to one or more C-frames for installation

PROFIL® application engineers work directly with our customers to service pre-production installations and testing. As a systems supplier, we engineer and provide the appropriate processing technology that is tailored to meet each application’s individual production requirements.

PROFIL® solutions for Press Hardened Steel (PHS)

Press Hardened Steel (PHS) is playing an increasingly important role in current and future car body architectures. Whether it is the protection of occupants in the event of a crash or the structural housing of the battery in electric vehicles, these steel grades are almost indispensable. Get to know the PROFIL® solutions for ultra-high-strength steels and their potential for process integration, enabling you to realise a reduction in the manufacturing process in addition to increasing the quality of your products.

Learn about how we cover you from technical advisory through after-sales support with the PROFIL® closed loop solution.