Specifications

| Size | Measurement |

|---|---|

| M6 | 0.70mm - 2.50mm |

| M8 | 0.70mm - 2.50mm |

| M10 | 1.00mm - 3.00mm |

| M12 | 1.50mm - 3.50mm |

Application Area

- Can be universally used for component thicknesses from 0.7 to 3.5 mm and tensile strengths of up to 700 MPa

- Suitable for a wide range of high dynamic, static and impact load conditions

- Suitable for use where threaded fittings need to be resistant to high axial forces

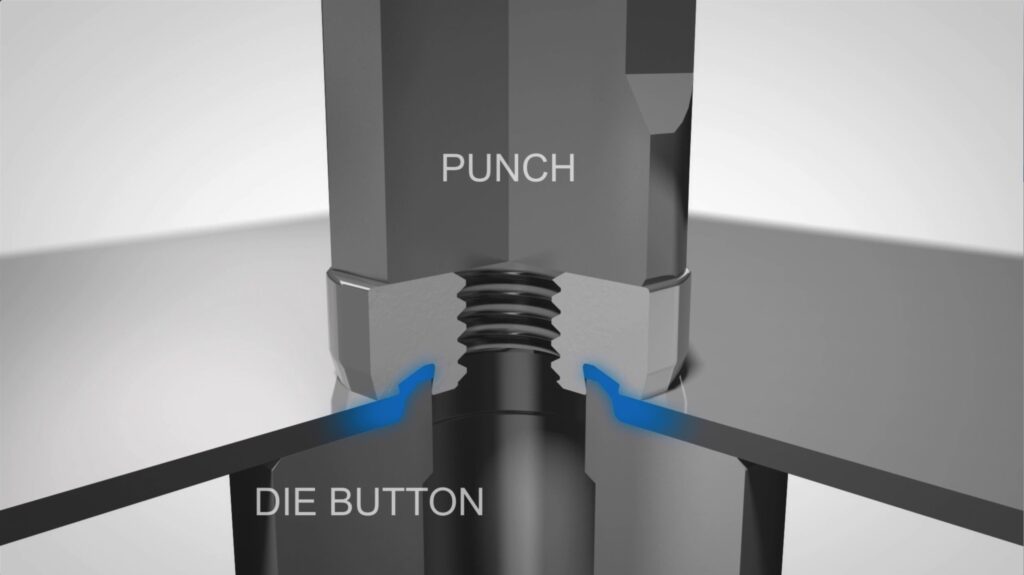

- Designed to be a self-piercing nut

- Suitable for use with surface-treated, galvanized or painted components

Technical Characteristics

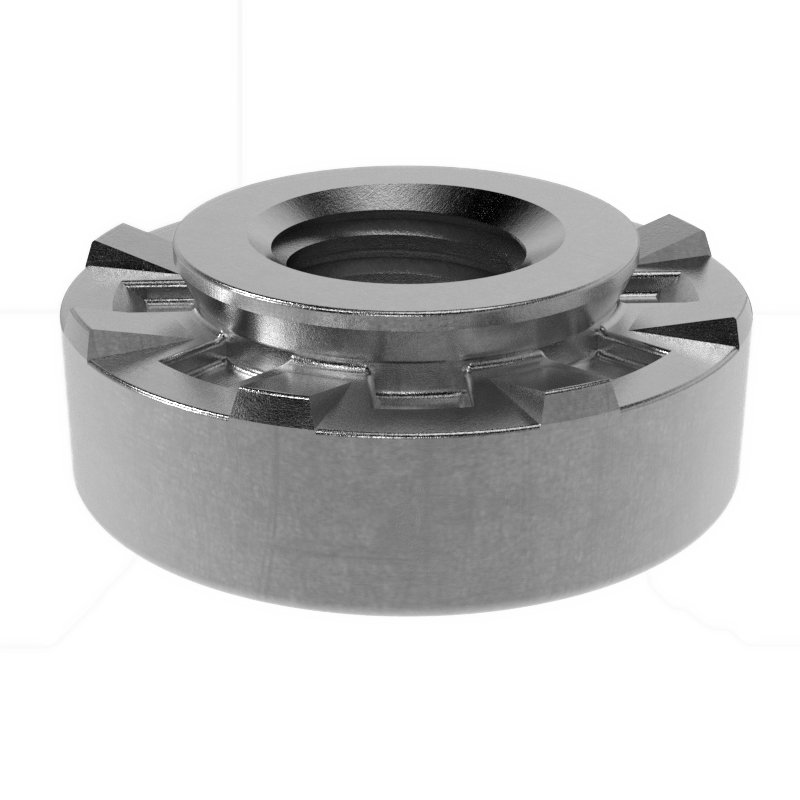

- Thread sizes: M6 to M12

- P.C. 10 (standard)

- Resistance to corrosion in accordance with the customer’s requirements

- No adverse effects on the joint or function of the thread; no damage due to weld spatters

- High resistance to twist and ejection forces, even for thin sheet metals

- Nut positioning tolerance ranges can be halved as compared to welding methods

- Straightforward, in-process and non-destructive quality testing possible by worker instead of elaborate destructive tests

Processing Steps

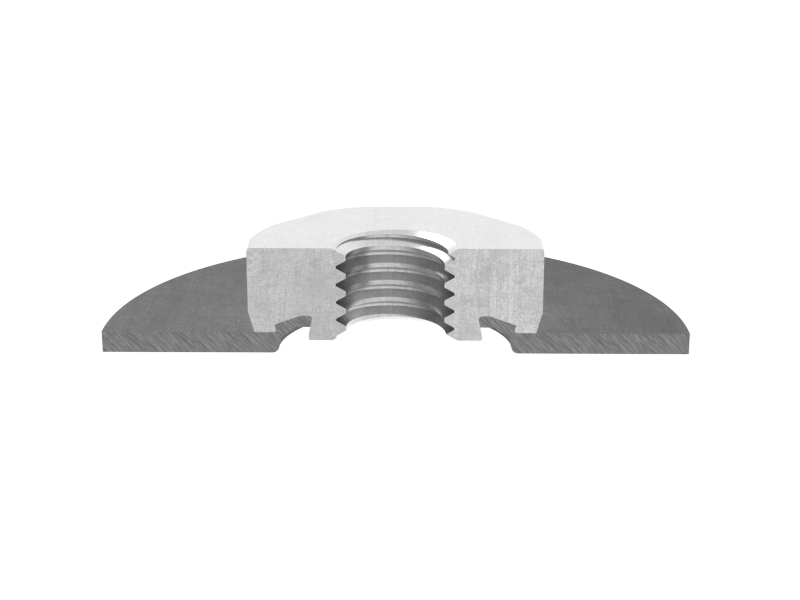

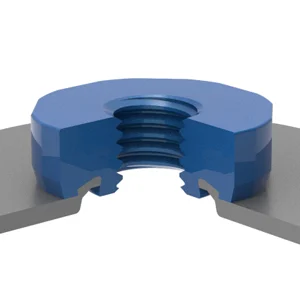

As delivered condition

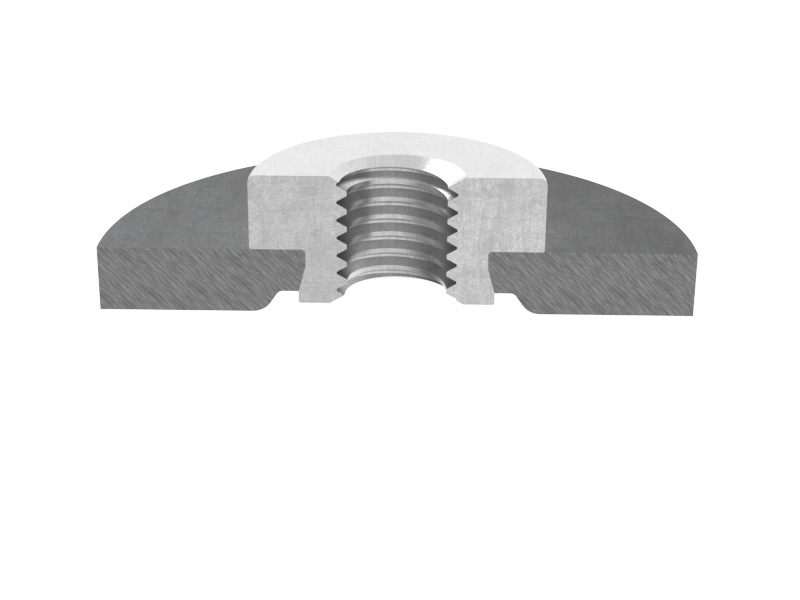

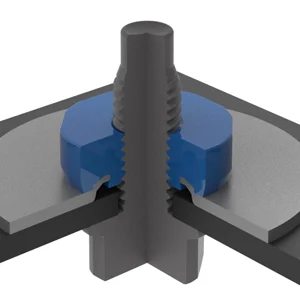

Processed

Assembled/screwed

Specifications

| Size | Measurement |

|---|---|

| M6 | 0.70mm - 2.50mm |

| M8 | 0.70mm - 2.50mm |

| M10 | 1.00mm - 3.00mm |

| M12 | 1.50mm - 3.50mm |