The industry’s proven partner, pioneering better fastening technology

End-to-end customer service trusted by the world’s leading automotive OEMs. We deliver on parts and partnership with best in class support at every stage of the journey. Our experience and expertise makes the PROFIL difference. We focus on you.

That’s why 100% of PROFIL customers rate the client experience as seamless.

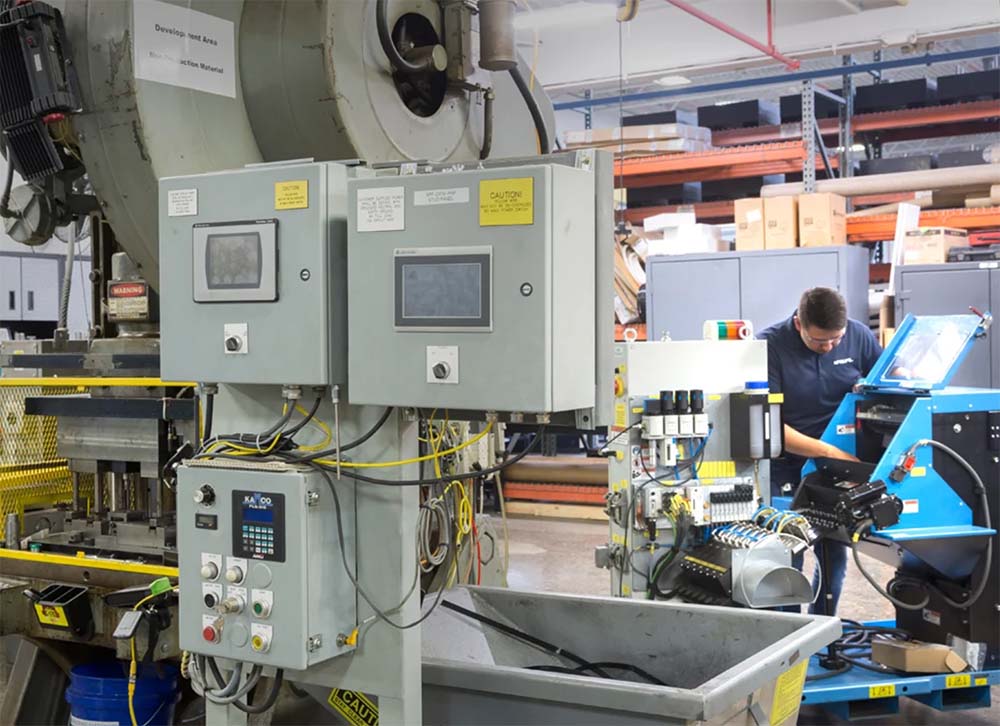

Cost saving industry – leading MAF technology. Automotive OEM’s who choose PROFIL drive down fastening costs and save time without compromising on quality.

99% of our partner OEM’s rated our In-Die installation process as flawless.

Giving you the competitive advantage in automotive fastening technology. Improving fastening performance for automotive OEMs through strength, reliability, flexibility. From water-tight seals to stronger joints and reduced weight.

99% of our partners are confident the change to MAF has positively impacted performance.

Stronger, cleaner automotive fastening that doesn’t cost the earth. PROFIL® MAF technology uses 80% less energy than traditional fastening methods, so we can grow a sustainable industry and a greener future.

[{"section_name":"Upper Body","section_cta":{"title":"Explore Upper Body Applications","url":"https:\/\/www.profil-global.com\/applications\/upper-body\/","target":""},"section_bg_image":{"ID":477,"id":477,"title":"upper-body","filename":"upper-body-1.webp","filesize":65274,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1.webp","link":"https:\/\/www.profil-global.com\/upper-body-3\/","alt":"","author":"1","description":"","caption":"","name":"upper-body-3","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:37:57","modified":"2024-05-20 14:37:57","menu_order":0,"mime_type":"image\/webp","type":"image","subtype":"webp","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/default.png","width":1920,"height":1080,"sizes":{"thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1-150×150.webp","thumbnail-width":150,"thumbnail-height":150,"medium":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1-300×169.webp","medium-width":300,"medium-height":169,"medium_large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1-768×432.webp","medium_large-width":768,"medium_large-height":432,"large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1-1024×576.webp","large-width":1024,"large-height":576,"1536×1536":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1-1536×864.webp","1536×1536-width":1536,"1536×1536-height":864,"2048×2048":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1.webp","2048×2048-width":1920,"2048×2048-height":1080,"small":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1-400×225.webp","small-width":400,"small-height":225,"massive":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1.webp","massive-width":1920,"massive-height":1080,"post-thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-1-800×600.webp","post-thumbnail-width":800,"post-thumbnail-height":600}},"section_video_in":{"ID":478,"id":478,"title":"upper-body-in-low","filename":"upper-body-in-low.mp4","filesize":759057,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-in-low.mp4","link":"https:\/\/www.profil-global.com\/upper-body-in-low\/","alt":"","author":"1","description":"","caption":"","name":"upper-body-in-low","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:38:00","modified":"2024-05-20 14:38:00","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"section_video_out":{"ID":479,"id":479,"title":"upper-body-out-low","filename":"upper-body-out-low.mp4","filesize":555106,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/upper-body-out-low.mp4","link":"https:\/\/www.profil-global.com\/upper-body-out-low\/","alt":"","author":"1","description":"","caption":"","name":"upper-body-out-low","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:38:01","modified":"2024-05-20 14:38:01","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"areas":[{"area_name":"Front end","area_desc":"Fender Mounting Bracket, FEM and RAD Support, Cowl\/Plenum","marker_position":{"x":"22","y":"63"}},{"area_name":"Side and Upper body","area_desc":"A, B, C & D Pillar, Sunroof Ring, Roof Rail, Seat Belt Turning Loop, Side Airbag","marker_position":{"x":"56","y":"31"}},{"area_name":"Rear end","area_desc":"Body Hinge (lift gate, trunk), Fuel Fill Grounding","marker_position":{"x":"74","y":"27"}}]},{"section_name":"Under Body","section_cta":{"title":"Explore Under Body Applications","url":"https:\/\/www.profil-global.com\/applications\/under-body\/","target":""},"section_bg_image":{"ID":483,"id":483,"title":"under-body","filename":"under-body-1.webp","filesize":58454,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1.webp","link":"https:\/\/www.profil-global.com\/under-body-3\/","alt":"","author":"1","description":"","caption":"","name":"under-body-3","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:39:09","modified":"2024-05-20 14:39:09","menu_order":0,"mime_type":"image\/webp","type":"image","subtype":"webp","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/default.png","width":1920,"height":1080,"sizes":{"thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1-150×150.webp","thumbnail-width":150,"thumbnail-height":150,"medium":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1-300×169.webp","medium-width":300,"medium-height":169,"medium_large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1-768×432.webp","medium_large-width":768,"medium_large-height":432,"large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1-1024×576.webp","large-width":1024,"large-height":576,"1536×1536":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1-1536×864.webp","1536×1536-width":1536,"1536×1536-height":864,"2048×2048":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1.webp","2048×2048-width":1920,"2048×2048-height":1080,"small":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1-400×225.webp","small-width":400,"small-height":225,"massive":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1.webp","massive-width":1920,"massive-height":1080,"post-thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-1-800×600.webp","post-thumbnail-width":800,"post-thumbnail-height":600}},"section_video_in":{"ID":486,"id":486,"title":"under-body-in-low","filename":"under-body-in-low.mp4","filesize":744313,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-in-low.mp4","link":"https:\/\/www.profil-global.com\/under-body-in-low\/","alt":"","author":"1","description":"","caption":"","name":"under-body-in-low","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:39:25","modified":"2024-05-20 14:39:25","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"section_video_out":{"ID":485,"id":485,"title":"under-body-out-low","filename":"under-body-out-low.mp4","filesize":526418,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/under-body-out-low.mp4","link":"https:\/\/www.profil-global.com\/under-body-out-low\/","alt":"","author":"1","description":"","caption":"","name":"under-body-out-low","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:39:24","modified":"2024-05-20 14:39:24","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"areas":[{"area_name":"Suspension","area_desc":"Shock Tower","marker_position":{"x":"27","y":"47"}},{"area_name":"Under Frame","area_desc":"Cross Car Beams, Oil Pan, Engine Mount Brackets, Front Rails, Crash Boxes","marker_position":{"x":"34","y":"60"}},{"area_name":"Floor","area_desc":"Floor Pan (sealed joint), Seat Belt Retractor, Transmission Tunnels (sealed joint), Subwoofer\/Amplifier, Seat Anchor","marker_position":{"x":"57","y":"47"}}]},{"section_name":"Closures","section_cta":{"title":"Explore Closures","url":"https:\/\/www.profil-global.com\/applications\/closures\/","target":""},"section_bg_image":{"ID":492,"id":492,"title":"closures-opened","filename":"closures-opened-1.webp","filesize":78116,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1.webp","link":"https:\/\/www.profil-global.com\/closures-opened-2\/","alt":"","author":"1","description":"","caption":"","name":"closures-opened-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:40:09","modified":"2024-05-20 14:40:09","menu_order":0,"mime_type":"image\/webp","type":"image","subtype":"webp","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/default.png","width":1920,"height":1080,"sizes":{"thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1-150×150.webp","thumbnail-width":150,"thumbnail-height":150,"medium":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1-300×169.webp","medium-width":300,"medium-height":169,"medium_large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1-768×432.webp","medium_large-width":768,"medium_large-height":432,"large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1-1024×576.webp","large-width":1024,"large-height":576,"1536×1536":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1-1536×864.webp","1536×1536-width":1536,"1536×1536-height":864,"2048×2048":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1.webp","2048×2048-width":1920,"2048×2048-height":1080,"small":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1-400×225.webp","small-width":400,"small-height":225,"massive":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1.webp","massive-width":1920,"massive-height":1080,"post-thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-opened-1-800×600.webp","post-thumbnail-width":800,"post-thumbnail-height":600}},"section_video_in":{"ID":493,"id":493,"title":"closures-in-low","filename":"closures-in-low-1.mp4","filesize":953664,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-in-low-1.mp4","link":"https:\/\/www.profil-global.com\/closures-in-low-2\/","alt":"","author":"1","description":"","caption":"","name":"closures-in-low-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:40:12","modified":"2024-05-20 14:40:12","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"section_video_out":{"ID":494,"id":494,"title":"closures-out-low","filename":"closures-out-low-1.mp4","filesize":602708,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/closures-out-low-1.mp4","link":"https:\/\/www.profil-global.com\/closures-out-low-2\/","alt":"","author":"1","description":"","caption":"","name":"closures-out-low-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:40:12","modified":"2024-05-20 14:40:12","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"areas":[{"area_name":"Hood","area_desc":"Hood Hinges, Hood Latch, Hood Striker","marker_position":{"x":"21","y":"61"}},{"area_name":"Door","area_desc":"Door Inner Panel, Door Hinge, Window Regulators, Side Intrusion Beams","marker_position":{"x":"59","y":"51"}},{"area_name":"Trunk","area_desc":"Tailgate Ball-hinge Brackets, Tailgate Inner Panel, Liftgate Panel, Liftgate Latch, Deck Lid Hinge","marker_position":{"x":"72","y":"13"}}]},{"section_name":"Chassis","section_cta":{"title":"Explore Chassis","url":"https:\/\/www.profil-global.com\/applications\/chassis\/","target":""},"section_bg_image":{"ID":497,"id":497,"title":"chassis","filename":"chassis-2.webp","filesize":114702,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2.webp","link":"https:\/\/www.profil-global.com\/chassis-2\/","alt":"","author":"1","description":"","caption":"","name":"chassis-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:40:49","modified":"2024-05-20 14:40:49","menu_order":0,"mime_type":"image\/webp","type":"image","subtype":"webp","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/default.png","width":1920,"height":1080,"sizes":{"thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2-150×150.webp","thumbnail-width":150,"thumbnail-height":150,"medium":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2-300×169.webp","medium-width":300,"medium-height":169,"medium_large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2-768×432.webp","medium_large-width":768,"medium_large-height":432,"large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2-1024×576.webp","large-width":1024,"large-height":576,"1536×1536":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2-1536×864.webp","1536×1536-width":1536,"1536×1536-height":864,"2048×2048":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2.webp","2048×2048-width":1920,"2048×2048-height":1080,"small":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2-400×225.webp","small-width":400,"small-height":225,"massive":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2.webp","massive-width":1920,"massive-height":1080,"post-thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-2-800×600.webp","post-thumbnail-width":800,"post-thumbnail-height":600}},"section_video_in":{"ID":498,"id":498,"title":"chassis-in-low","filename":"chassis-in-low-2.mp4","filesize":675080,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-in-low-2.mp4","link":"https:\/\/www.profil-global.com\/chassis-in-low-2\/","alt":"","author":"1","description":"","caption":"","name":"chassis-in-low-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:40:52","modified":"2024-05-20 14:40:52","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"section_video_out":{"ID":499,"id":499,"title":"chassis-out-low","filename":"chassis-out-low-2.mp4","filesize":444168,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/chassis-out-low-2.mp4","link":"https:\/\/www.profil-global.com\/chassis-out-low-2\/","alt":"","author":"1","description":"","caption":"","name":"chassis-out-low-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:40:53","modified":"2024-05-20 14:40:53","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"areas":[{"area_name":"Suspension","area_desc":"Front and Rear Sway Bar, Track Bar, Shock Tower","marker_position":{"x":"29","y":"68"}},{"area_name":"Frame","area_desc":"Cross Member, Frame Rails, Crash Boxes","marker_position":{"x":"48","y":"58"}},{"area_name":"Attachments","area_desc":"Trailer Hitch Mounts, Spare Tire Mount, Kick Up Rails, Fuel and Brake Line Mount, CAC Mounting, Rear Brake Junction Block","marker_position":{"x":"68","y":"24"}}]},{"section_name":"Seating","section_cta":{"title":"Explore Seating","url":"https:\/\/www.profil-global.com\/applications\/seating\/","target":""},"section_bg_image":{"ID":505,"id":505,"title":"seat-frame","filename":"seat-frame.webp","filesize":45516,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame.webp","link":"https:\/\/www.profil-global.com\/seat-frame\/","alt":"","author":"1","description":"","caption":"","name":"seat-frame","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:41:24","modified":"2024-05-20 14:41:24","menu_order":0,"mime_type":"image\/webp","type":"image","subtype":"webp","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/default.png","width":1920,"height":1080,"sizes":{"thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame-150×150.webp","thumbnail-width":150,"thumbnail-height":150,"medium":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame-300×169.webp","medium-width":300,"medium-height":169,"medium_large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame-768×432.webp","medium_large-width":768,"medium_large-height":432,"large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame-1024×576.webp","large-width":1024,"large-height":576,"1536×1536":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame-1536×864.webp","1536×1536-width":1536,"1536×1536-height":864,"2048×2048":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame.webp","2048×2048-width":1920,"2048×2048-height":1080,"small":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame-400×225.webp","small-width":400,"small-height":225,"massive":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame.webp","massive-width":1920,"massive-height":1080,"post-thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seat-frame-800×600.webp","post-thumbnail-width":800,"post-thumbnail-height":600}},"section_video_in":{"ID":504,"id":504,"title":"seating-in-low","filename":"seating-in-low.mp4","filesize":2508670,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seating-in-low.mp4","link":"https:\/\/www.profil-global.com\/seating-in-low\/","alt":"","author":"1","description":"","caption":"","name":"seating-in-low","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:41:24","modified":"2024-05-20 14:41:24","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1920,"height":1080},"section_video_out":{"ID":503,"id":503,"title":"seating-out-low","filename":"seating-out-low.mp4","filesize":810758,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/seating-out-low.mp4","link":"https:\/\/www.profil-global.com\/seating-out-low\/","alt":"","author":"1","description":"","caption":"","name":"seating-out-low","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:41:22","modified":"2024-05-20 14:41:22","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1920,"height":1080},"areas":[{"area_name":"Cushion Mounting","area_desc":"","marker_position":{"x":"32","y":"64"}},{"area_name":"Cushion Frame","area_desc":"","marker_position":{"x":"36","y":"68"}},{"area_name":"Side Frame","area_desc":"","marker_position":{"x":"53","y":"78"}},{"area_name":"Mounting Rail","area_desc":"","marker_position":{"x":"55","y":"82"}},{"area_name":"Seat Belt Mounting","area_desc":"","marker_position":{"x":"62","y":"66"}},{"area_name":"Pivot Point Seat Back","area_desc":"","marker_position":{"x":"62","y":"52"}}]},{"section_name":"Battery Housing","section_cta":{"title":"Explore Battery Housing","url":"https:\/\/www.profil-global.com\/applications\/battery-tray\/","target":""},"section_bg_image":{"ID":507,"id":507,"title":"battery-tray-upright","filename":"battery-tray-upright-1.webp","filesize":47978,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1.webp","link":"https:\/\/www.profil-global.com\/battery-tray-upright-2\/","alt":"","author":"1","description":"","caption":"","name":"battery-tray-upright-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:42:15","modified":"2024-05-20 14:42:15","menu_order":0,"mime_type":"image\/webp","type":"image","subtype":"webp","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/default.png","width":1920,"height":1080,"sizes":{"thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1-150×150.webp","thumbnail-width":150,"thumbnail-height":150,"medium":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1-300×169.webp","medium-width":300,"medium-height":169,"medium_large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1-768×432.webp","medium_large-width":768,"medium_large-height":432,"large":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1-1024×576.webp","large-width":1024,"large-height":576,"1536×1536":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1-1536×864.webp","1536×1536-width":1536,"1536×1536-height":864,"2048×2048":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1.webp","2048×2048-width":1920,"2048×2048-height":1080,"small":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1-400×225.webp","small-width":400,"small-height":225,"massive":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1.webp","massive-width":1920,"massive-height":1080,"post-thumbnail":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-tray-upright-1-800×600.webp","post-thumbnail-width":800,"post-thumbnail-height":600}},"section_video_in":{"ID":509,"id":509,"title":"battery-housing-in-low","filename":"battery-housing-in-low-1.mp4","filesize":863165,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-housing-in-low-1.mp4","link":"https:\/\/www.profil-global.com\/battery-housing-in-low-2\/","alt":"","author":"1","description":"","caption":"","name":"battery-housing-in-low-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:42:18","modified":"2024-05-20 14:42:18","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"section_video_out":{"ID":508,"id":508,"title":"battery-housing-out-low","filename":"battery-housing-out-low-1.mp4","filesize":538493,"url":"https:\/\/www.profil-global.com\/wp-content\/uploads\/2024\/05\/battery-housing-out-low-1.mp4","link":"https:\/\/www.profil-global.com\/battery-housing-out-low-2\/","alt":"","author":"1","description":"","caption":"","name":"battery-housing-out-low-2","status":"inherit","uploaded_to":0,"date":"2024-05-20 14:42:17","modified":"2024-05-20 14:42:17","menu_order":0,"mime_type":"video\/mp4","type":"video","subtype":"mp4","icon":"https:\/\/www.profil-global.com\/wp-includes\/images\/media\/video.png","width":1280,"height":720},"areas":[{"area_name":"Floor Pan","area_desc":"Floor Pan (sealed joint)","marker_position":{"x":"50","y":"70"}},{"area_name":"Cell Retainers","area_desc":"","marker_position":{"x":"49","y":"51"}},{"area_name":"Cell Locating Pins","area_desc":"","marker_position":{"x":"55","y":"47"}},{"area_name":"Mounting Rails","area_desc":"","marker_position":{"x":"40","y":"30"}},{"area_name":"Cross members","area_desc":"","marker_position":{"x":"51","y":"22"}},{"area_name":"Extrusion\/Side Rails","area_desc":"","marker_position":{"x":"74","y":"31"}}]}]

Automotive Mechanically Attached Fastening Applications

Upper Body Front end Fender Mounting Bracket, FEM and RAD Support, Cowl/Plenum

Side and Upper body A, B, C & D Pillar, Sunroof Ring, Roof Rail, Seat Belt Turning Loop, Side Airbag

Rear end Body Hinge (lift gate, trunk), Fuel Fill Grounding

Explore Upper Body Applications Under Body Suspension Shock Tower

Under Frame Cross Car Beams, Oil Pan, Engine Mount Brackets, Front Rails, Crash Boxes

Floor Floor Pan (sealed joint), Seat Belt Retractor, Transmission Tunnels (sealed joint), Subwoofer/Amplifier, Seat Anchor

Explore Under Body Applications Closures Hood Hood Hinges, Hood Latch, Hood Striker

Door Door Inner Panel, Door Hinge, Window Regulators, Side Intrusion Beams

Trunk Tailgate Ball-hinge Brackets, Tailgate Inner Panel, Liftgate Panel, Liftgate Latch, Deck Lid Hinge

Explore Closures Chassis Suspension Front and Rear Sway Bar, Track Bar, Shock Tower

Frame Cross Member, Frame Rails, Crash Boxes

Attachments Trailer Hitch Mounts, Spare Tire Mount, Kick Up Rails, Fuel and Brake Line Mount, CAC Mounting, Rear Brake Junction Block

Explore Chassis Seating Cushion Mounting

Cushion Frame

Side Frame

Mounting Rail

Seat Belt Mounting

Pivot Point Seat Back

Explore Seating Battery Housing Floor Pan Floor Pan (sealed joint)

Cell Retainers

Cell Locating Pins

Mounting Rails

Cross members

Extrusion/Side Rails

Explore Battery Housing

Upper Body

Under Body

Closures

Chassis

Seating

Battery Housing

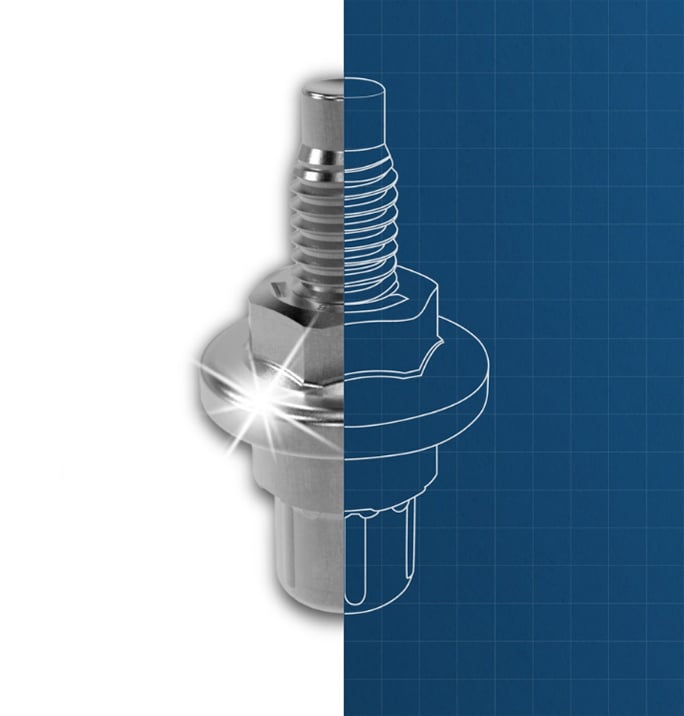

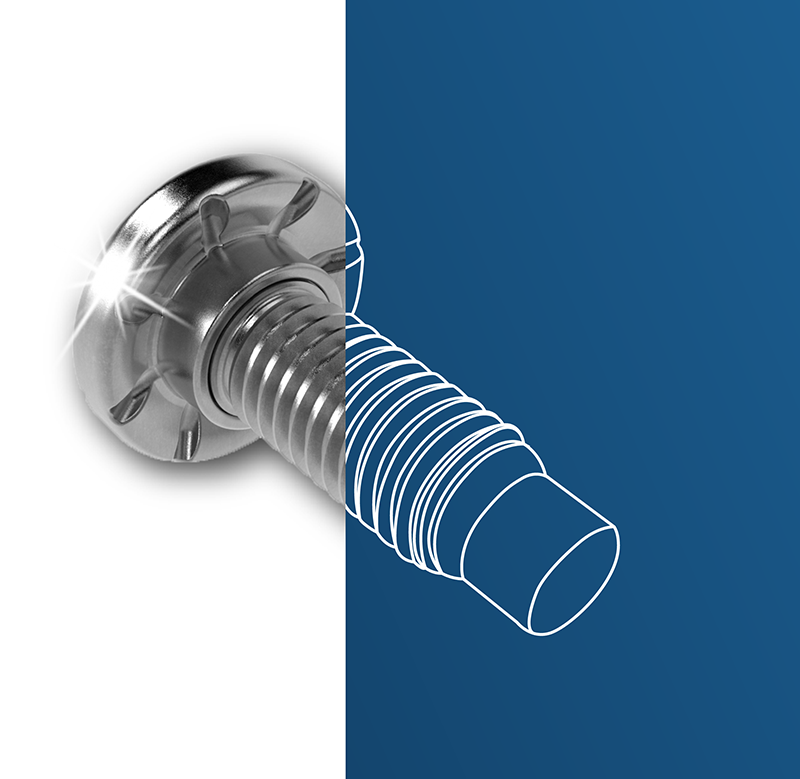

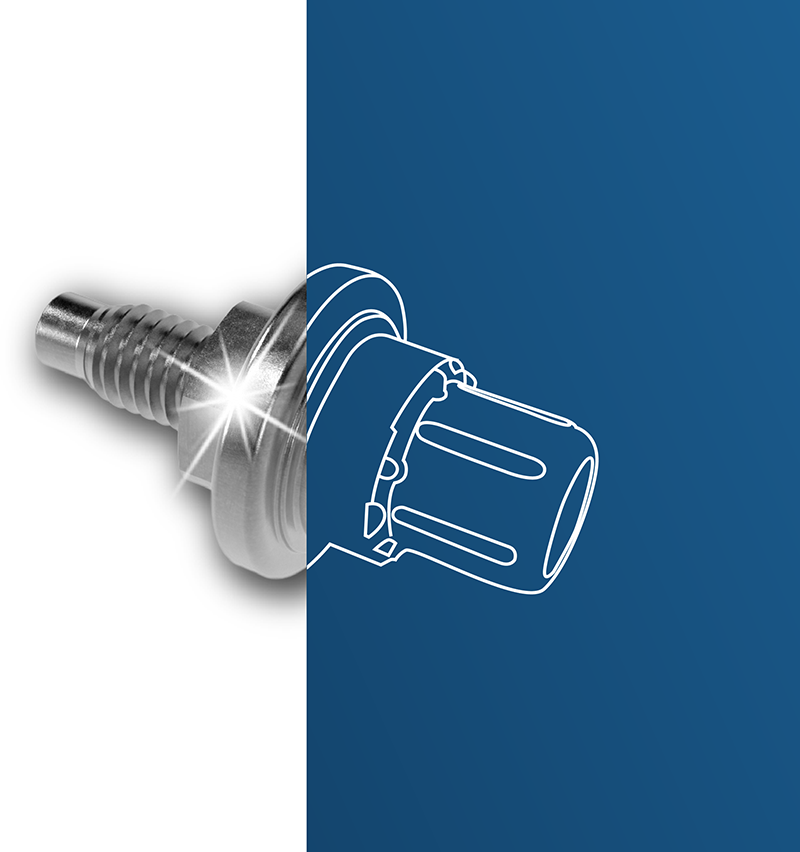

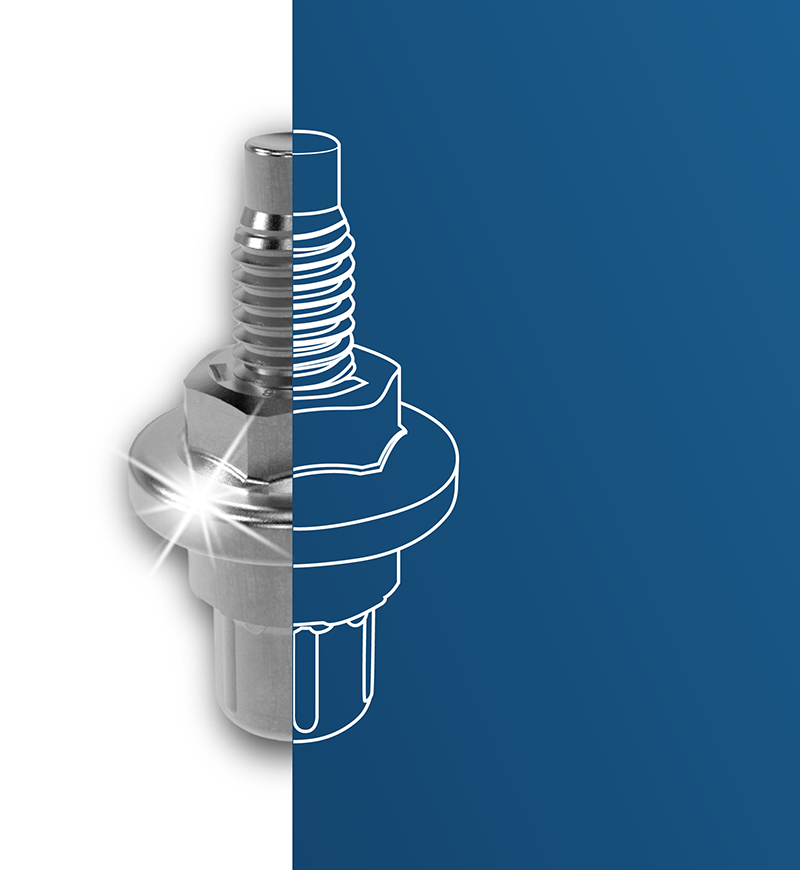

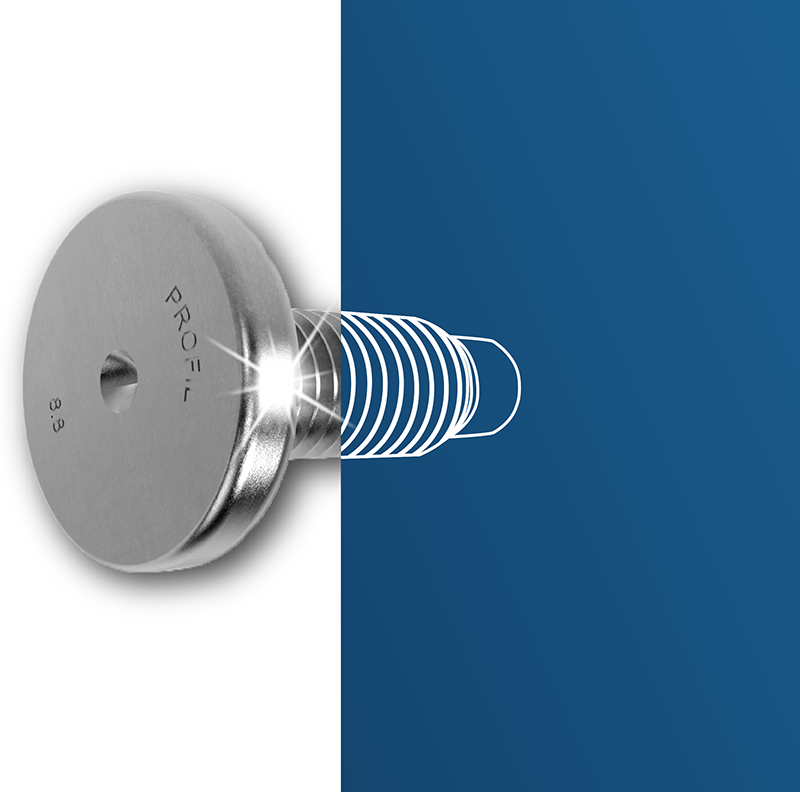

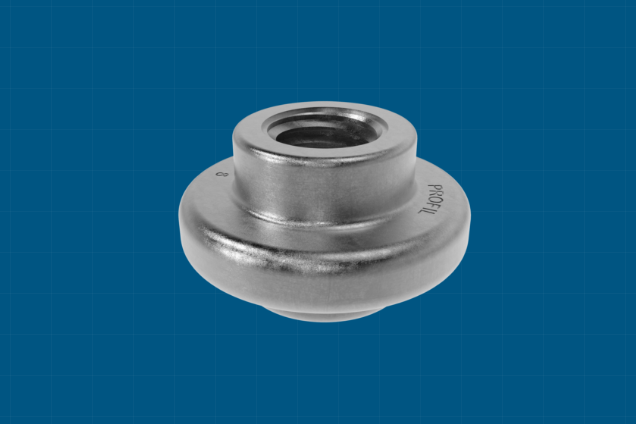

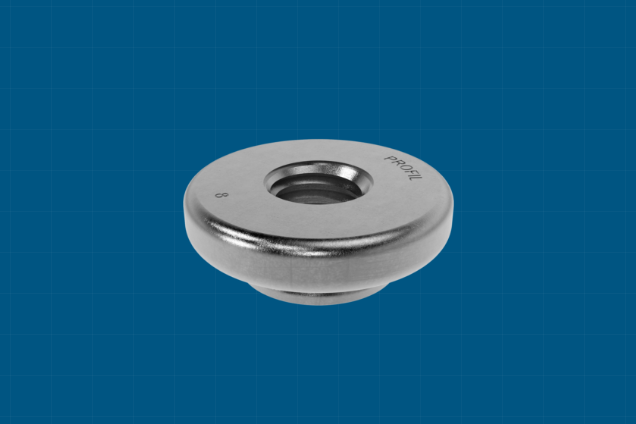

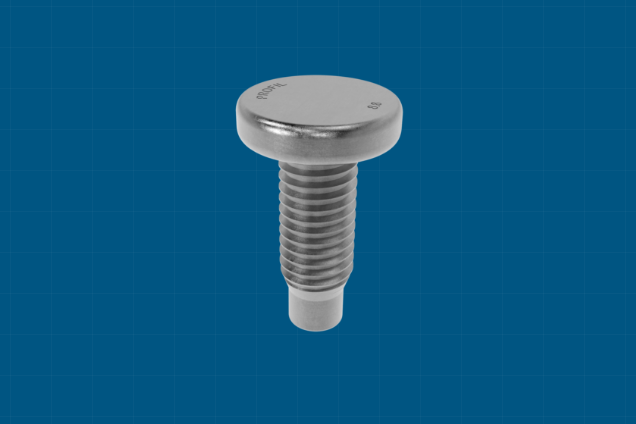

About PROFIL® PROFIL® is a global leader in Mechanically Attached Fasteners (MAF), offering a robust alternative to weld fasteners for the automotive industry. Our precision-engineered fastening solutions are known for their strength, durability, and safety, making us a trusted partner for automotive manufacturers and suppliers around the world. From assembly to structural connections, PROFIL® provides a comprehensive range of fastening products designed to meet the automotive industry’s dynamic requirements.

Read more

About PROFIL®

Cost effective, industry – leading MAF technology Automotive OEMs who choose PROFIL drive down fastening costs and save time without compromising quality.

99% of our partner OEMs rated our in-die installation process as flawless.

End-to-end customer service trusted by the world’s leading automotive OEMs Automotive OEMs who choose PROFIL drive down fastening costs and save time without compromising quality.

100% of our partner OEMs rated our in-die installation process as flawless.

Stronger, cleaner automotive fastening that doesn’t cost the earth

50% less energy used with PROFIL MAF than traditional fastening methods, so we can grow a sustainable industry and a greener future.

Giving you the competitive advantage in automotive fastening technology Improving fastening performance for automotive OEMs through strength, reliability, flexibility. From water-tight seals to stronger joints and reduced weight.

95% of our partner are confident the change to MAF has positively impacted performance.

PROFIL® is part of a full range of PennEngineering’s® eMobility solutions Learn more here: https://emobilitysolutions.com/

Technical Advisory Global field engineering and direct sales engineers

Manufacturing Global manufacturing capabilities in local markets

Application Engineering Worldwide application engineering experts and full test lab capabilities

After Sales Full, ongoing technical support and on-site training as required

Parts installed per day

parts sold in 2022

Founded in 1965

Explore our products PROFIL® Mechanically Attached Fasteners (MAF) provide a clean, cost-effective, and high performing alternative to weld fasteners for virtually any automotive structural application, including those within the upper body, under body, closures, EV battery trays, and truck chassis. Because the fasteners are joined to the application mechanically, they can be installed in the in-die process, which eliminates the need for a secondary operation and reduces operating costs.

Use Our In-Die See how you can reduce total installed cost and boost efficiency with our free In-Die Cost Calculator.